Linear Heat Detectors

Designed for use in a wide variety of indoor and outdoor applications, Linear heat fire alarm cables are particularly suited for applications which require fire detection within close proximity or in harsh environments where other forms of fire detection are ineffective.

Digital Temperature Sensing

Fiber Optic Linear Heat

Measures temperatures in real time along the length of the fiber optic cable by transmitting pulses of laser light and analyzing the return signal. Distributed temperature sensing (DTS) allows fast response and precise location identification in the early stages of fire on cable runs up to six miles.

- Fully Customizable

-

Particularly suited for large-scale infrastructures, AP Sensing allows for a variety of alarm criteria on the same cable run (up to 256 zones and 44 relays) and may detect set temperature thresholds, temperature rate of rise or difference to zone average.

- Temperature Visualization

-

SmartVision™ software visualizes real-time temperature readings, alarm zones and operational status throughout the cable run of your application. The software also records temperature history, so trends may be monitored and preventative measures may be performed.

- Acoustics Monitoring

-

Distributed Acoustics Monitoring (DAS) systems are available to detect vibrations and capture acoustic energy along optical fibers, which is useful to detect fuel leaks in a pipe or digging around sensitive areas.

- Immune To Elements

-

The AP Sensing cable can withstand industrial environments with dust, dirt, corrosion and temperatures as high as 1382°F – almost 500°F than any other fire detection system without losing monitoring capability. All cables have an expected lifespan of 30 years and are maintenance-free.

Protectowire

Linear Heat Cable

Detects early stages of fire when increased heat melts a heat-reactive polymer which coats two steel conductors. When the two conductors touch, an electrical short occurs and the connected PIM-530 module relays the information to the fire panel.

- CTI False Alarm Protection

-

Within standard linear heat cables, accidental activation may occur, such as if a forklift damages a cable and the two conductors make contact. Confirmed Temperature Initiation (CTI) protects against accidental alarms and discharge by confirming the temperature where the conductors were activated. If the temperature is normal, the CTM-530 module will trigger a “short fault” status, indicating mechanical activation or damage of the conductors.

- Application-Specific Jackets

-

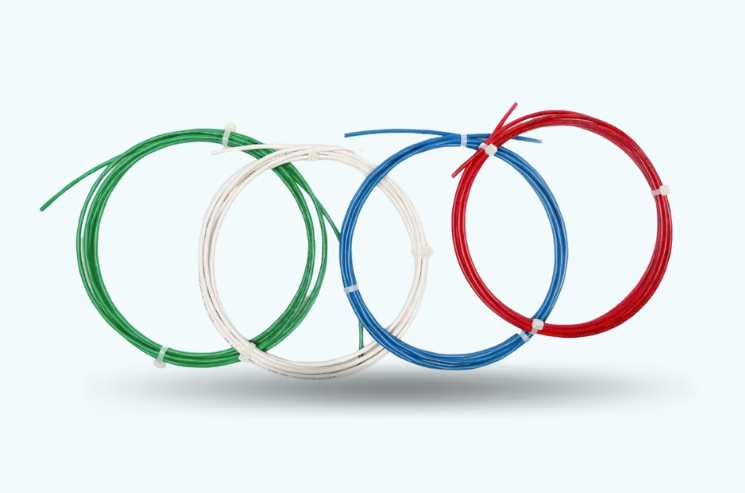

Linear heat cables use four different jacket types for various applications and environments:

- EPC & CTI (Polyvinyl Chloride) – Ideal for general, multi-purpose applications.

- Type XCR & CTI-X (Fluoropolymer) – Ideal for extreme environments and includes excellent resistance to chemicals and UV.

- Type XLT (Proprietary Polymer) – Ideal for low temperature environmental performance such as cold storage; only digital linear heat detector rated at 135°F alarm temperature.

- Type PLR (Polypropylene Elastomer) – Ideal for applications located outside and requiring long runs of cable.

- Cost-Effective

-

For many applications, Protectowire linear heat cables offer the most cost-effective solution to provide heat detection along a very large environment, such as a tunnel, refrigerator or conveyor belt.

How does linear heat detection work?

1. Cable Installed

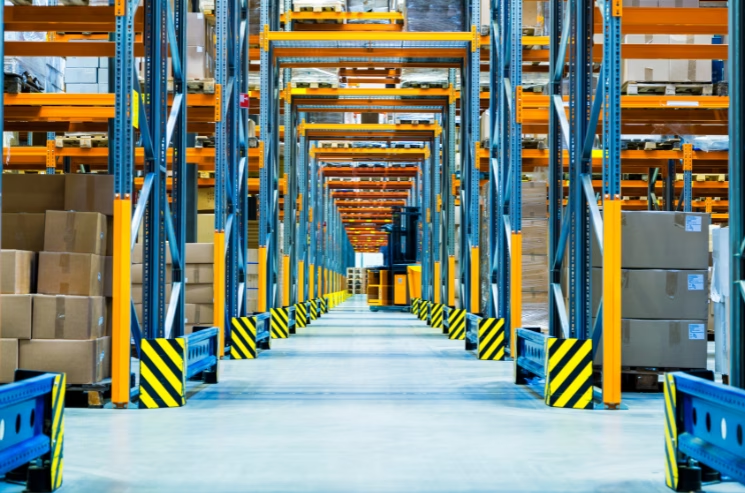

A linear heat cable is strategically routed throughout a large environment, such as a tunnel or warehouse

4. Fire Panel Activates

The respective modules will identify the location of the alert and will relay the information to the connected fire panel. Depending on the type of alert, the fire panel may go into alarm, activating horns and strobes or pre-programmed voice evacuation functions to quickly evacuate building occupants. It may also notify nearby occupants of the impending release of suppression systems.

2. Fire Detected - Protectowire

In the Protectowire cable are two zinc-coated spring steel conductors, individually coated with a heat-sensitive thermoplastic polymer. When elevated temperatures occur, the polymer in that segment of the cable will melt and create an electrical short.

5. BMS Activates

If the fire panel is integrated with building management systems, it may activate ventilation systems, unlock doors and recall any elevators.

3. Fire Detected - Digital Temperature Sensing

In the Digital Temperature Sensing cable, an optical laser pulse is continuously sent through the fiber optic cable, which results in scattered light reflecting back to the transmitting end, where the information is analyzed and elevated temperatures are quickly identified.

6. Suppression Flows

If applicable, a releasing panel will activate relays to dispense pre-action sprinkler systems or special hazard suppression such as a chemical agent or water mist onto the specific space identified along the linear heat cable

What environments are ideal for fiber optic linear heat detection?

Linear heat cables by Protectowire are also a cost-effective solution in many of the applications below; however, it will not generate real-time temperature data nor can it set specific temperature thresholds along certain segments of the cable.

1. Tunnels

Used in traffic/rail tunnels to quickly detect vehicle fires or in difficult-to-access electrical cable tunnels to identify the early stages of an electrical fire. Also may monitor temperature spike trends so preventative maintenance may be performed before a fire does occur

4. Warehouses & Production Areas

In large, dusty environments where air sampling may be difficult, flexible fiber optic linear heat cables may be strategically routed to detect early stages of fire from electrical shorts, overheated or malfunctioning equipment and most other sources.

2. Conveyor Belts

Provides real-time temperature monitoring with the purpose of implementing a preventative (and not simply reactive) system that is able to anticipate critical conditions and generate pre-alarms for abnormal temperature conditions.

3. Battery Energy Storage

Routed throughout lithium ion battery racks to identify the early stages of thermal runaway. When certain temperature thresholds are met, the connected Fike fire panel may initialize the BMS system to shut down power to the overheated battery system.